Detecting an Abnormal Motor Field Current Level

Motor field current are typically adjusted at a 100 % of the motor field current rating to maximize the available motor torque. Shifts or drifts in the field level can hinder the performance of the machine, particularly during accel where motors are most solicited and could lead to motor damage if outside of tolerances.

Such issues can result from defects in the drive field control card or a faulty field measurement by the drive. While legacy analog drives are more at risk of developing these problems, modern digital drives incorporate features which expose different risks such as auto calibration of analog inputs which can equally result in faulty feedbacks in the drive.

Detection

Following a short shutdown on one of our clients’ tissue machine, the drives were re-energized and the machine was restarted.

Behind the scenes, the drive firmware is designed to initiate a recalibration of all the drive analog inputs when drives are energized. Only this time, in the wire drive the field feedback signal was misread during the calibration sequence which threw off the calibration of the field feedback signal in the drive.

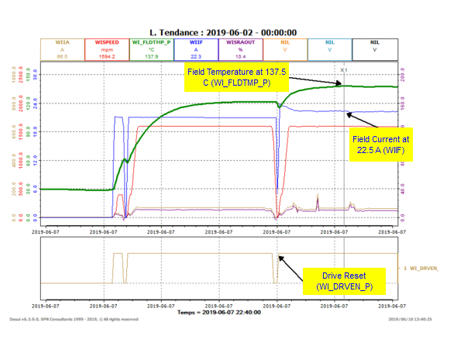

By having this machine under constant surveillance through the 90 kpis we calculate every hour, our specialists were alerted of this issue. Alarms were indicating that the motor field level was above the motor rating and the temperature had risen to a critical level at 137 C (279 F).

Our Intervention

We called the mill to alert of this issue to take action before the motor field over temperature results in permanent motor damage which would lead to major downtime. A detailed report followed.

Cycling the power on the wire drive resolved the issue, bringing the field and motor temperature within acceptable levels. Further investigation led us to identify that a drive firmware update is available which provides the possibility of only running the auto calibration on-demand.

Benefits

Early detection of this issue prevented motor damage which would have resulted in significant production losses by the time a new motor was located and installed.