Success Stories

The following case studies show how our solution brings value to our clients.

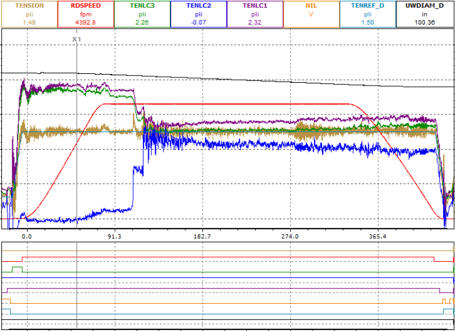

Hidden roll defect due to faulty valve connector

Rider roll load variations affect wound-in tension which can affect roll quality and resulting in poor performance in downstream processes. Detecting such anomalies can be challenging as they are intermittent in nature and their impact does not always translate into visual defects on the produced rolls..... Read more >

Incorrect selection of winding parameters

Winders run different grades, each requiring a specific set of winding parameters (torque, nip , tension), to produce rolls with optimal structure and free from defects...... Read more >

Bad roll quality due to a seized bearing

Abnormal deviation in tension due to defective tension control is likely to go undetected at the mill as the variations in the wound-in tension are often only detected when rolls are consumed at the press.... Read more >

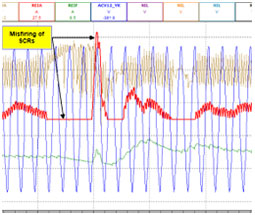

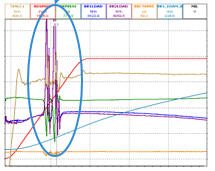

Capturing Intermittent Abnormal Drive SCR Firing

Whether dealing with legacy or modern digital drives, there is always a risk of abnormal SCR firing which can be difficult to troubleshoot without high speed data (2,500 samples/sec), otherwise leading to frequent interrupted production. Read more >

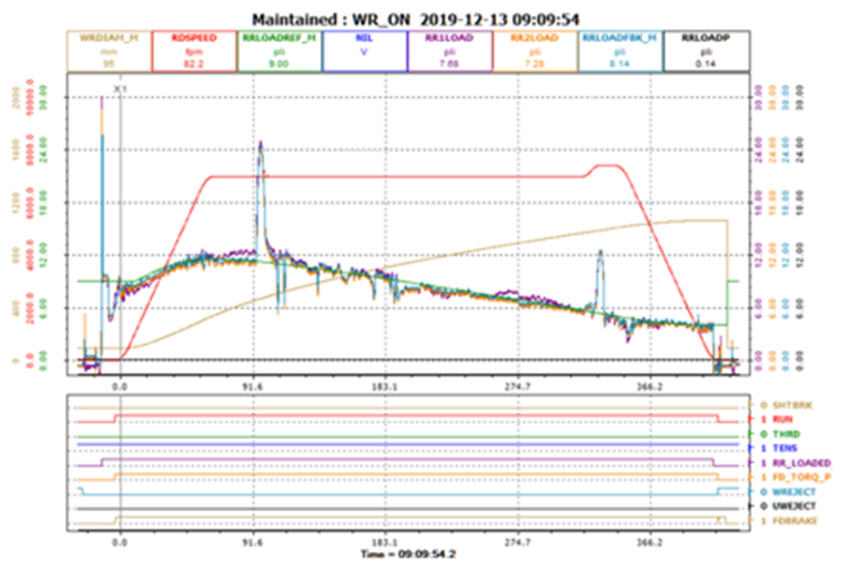

Uncovering Defective Rider Roll Load Cell

Shifts in load cell calibrations or defective load cells can be tricky to detect in closed loop systems, since the control is continuously aligning the load cell feedback signal on the reference. Monitoring independent transducers signals can achieve this. Read more >

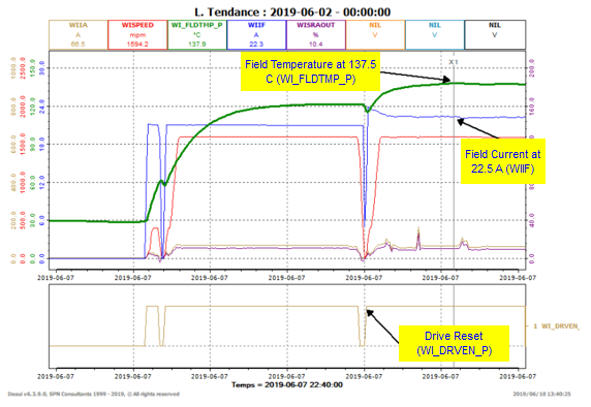

Detecting an Abnormal Motor Field Current Level

Motor field current level is one of these things which which is rarely monitored and while it affects available motor torque, it is a motor failure waiting to happen. Read more >

Tracking Drum Slippage

Drum slippage generally occur sporadically and for short bursts of time which can remain unseen while affecting roll structure and quality until further deterioration occurs. This would translate in variations this can be detection at first instance to take limit production loss.… Read more >

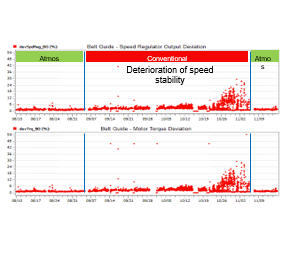

Slipping Motor Tach Coupling

A defective motor speed feedback will not always show obvious signs in the absence of a continuous high speed data analysis based on machine specific algorithms.... Read more >

Intermittent Malfunction of Hydraulic Valve

Sporadic and intermittent valve anomalies make them almost impossible to detect in the absence of a high resolution data acquisition and automated continuous analysis of pressure stability.... Read more >

There are many things that can cause the wound rolls to run together at the winder. Troubleshooting is much easier if we have verified the controls are operating properly.... Read more >